Chapter 16 Emergency Procedures

Table of Contents

Emergency Situations

Emergency Landings

Types of Emergency Landings

Psychological Hazards

Basic Safety Concepts

General

Attitude and Sink Rate Control

Terrain Selection

Airplane Configuration

Approach

Terrain Types

Confined Areas

Trees (Forest)

Water (Ditching) and Snow

Engine Failure After Takeoff (Single-Engine)

Emergency Descents

In-Flight Fire

Engine Fire

Electrical Fires

Cabin Fire

Flight Control Malfunction / Failure

Total Flap Failure

Asymmetric (Split) Flap

Loss of Elevator Control

Landing Gear Malfunction

Systems Malfunctions

Electrical System

Pitot-Static System

Abnormal Engine Instrument Indications

Door Opening In Flight

Inadvertent VFR Flight Into IMC

General

Recognition

Maintaining Airplane Control

Attitude Control

Turns

Climbs

Descents

Combined Maneuvers

Transition to Visual Flight

FLIGHT CONTROL MALFUNCTION/FAILURE

TOTAL FLAP FAILURE

The inability to extend the wing flaps will necessitate a no-flap approach and landing. In light airplanes a no- flap approach and landing is not particularly difficult or dangerous. However, there are certain factors which must be considered in the execution of this maneuver. A no-flap landing requires substantially more runway than normal. The increase in required landing distance could be as much as 50 percent.

When flying in the traffic pattern with the wing flaps retracted, the airplane must be flown in a relatively nose-high attitude to maintain altitude, as compared to flight with flaps extended. Losing altitude can be more of a problem without the benefit of the drag normally provided by flaps. A wider, longer traffic pattern may be required in order to avoid the necessity of diving to lose altitude and consequently building up excessive airspeed.

On final approach, a nose-high attitude can make it difficult to see the runway. This situation, if not anticipated, can result in serious errors in judgment of height and distance. Approaching the runway in a relatively nose-high attitude can also cause the perception that the airplane is close to a stall. This may cause the pilot to lower the nose abruptly and risk touching down on the nosewheel.

With the flaps retracted and the power reduced for landing, the airplane is slightly less stable in the pitch and roll axes. Without flaps, the airplane will tend to float considerably during roundout. The pilot should avoid the temptation to force the airplane onto the runway at an excessively high speed. Neither should the pilot flare excessively, because without flaps this might cause the tail to strike the runway.

ASYMMETRIC (SPLIT) FLAP

An asymmetric “split” flap situation is one in which one flap deploys or retracts while the other remains in position. The problem is indicated by a pronounced roll toward the wing with the least flap deflection when wing flaps are extended/retracted.

The roll encountered in a split flap situation is countered with opposite aileron. The yaw caused by the additional drag created by the extended flap will require substantial opposite rudder, resulting in a cross-control condition. Almost full aileron may be required to maintain a wings-level attitude, especially at the reduced airspeed necessary for approach and landing. The pilot therefore should not attempt to land with a crosswind from the side of the deployed flap, because the additional roll control required to counteract the crosswind may not be available.

16-8 Ch 16.qxd 5/7/04 10:30 AM Page 16-9The pilot must be aware of the difference in stall speeds between one wing and the other in a split flap situation. The wing with the retracted flap will stall considerably earlier than the wing with the deployed flap. This type of asymmetrical stall will result in an uncontrollable roll in the direction of the stalled (clean) wing. If altitude permits, a spin will result.

The approach to landing with a split flap condition should be flown at a higher than normal airspeed. The pilot should not risk an asymmetric stall and subsequent loss of control by flaring excessively. Rather, the airplane should be flown onto the runway so that the touchdown occurs at an airspeed consistent with a safe margin above flaps-up stall speed.

LOSS OF ELEVATOR CONTROL

In many airplanes, the elevator is controlled by two cables: a “down” cable and an “up” cable. Normally, a break or disconnect in only one of these cables will not result in a total loss of elevator control. In most airplanes, a failed cable results in a partial loss of pitch control. In the failure of the “up” elevator cable (the “down” elevator being intact and functional) the control yoke will move aft easily but produce no response. Forward yoke movement, however, beyond the neutral position produces a nosedown attitude. Conversely, a failure of the “down” elevator cable, forward movement of the control yoke produces no effect. The pilot will, however, have partial control of pitch attitude with aft movement.

When experiencing a loss of up-elevator control, the pilot can retain pitch control by:

- • Applying considerable nose-up trim.

- • Pushing the control yoke forward to attain and maintain desired attitude.

- • Increasing forward pressure to lower the nose and relaxing forward pressure to raise the nose.

- • Releasing forward pressure to flare for landing.

When experiencing a loss of down-elevator control, the pilot can retain pitch control by:

- • Applying considerable nosedown trim.

- • Pulling the control yoke aft to attain and maintain attitude.

- • Releasing back pressure to lower the nose and increasing back pressure to raise the nose.

- • Increasing back pressure to flare for landing.

Trim mechanisms can be useful in the event of an in-flight primary control failure. For example, if the linkage between the cockpit and the elevator fails in flight, leaving the elevator free to weathervane in the wind, the trim tab can be used to raise or lower the elevator, within limits. The trim tabs are not as effective as normal linkage control in conditions such as low airspeed, but they do have some positive effect— usually enough to bring about a safe landing.

If an elevator becomes jammed, resulting in a total loss of elevator control movement, various combinations of power and flap extension offer a limited amount of pitch control. A successful landing under these conditions, however, is problematical.

LANDING GEAR MALFUNCTION

Once the pilot has confirmed that the landing gear has in fact malfunctioned, and that one or more gear legs refuses to respond to the conventional or alternate methods of gear extension contained in the AFM/POH, there are several methods that may be useful in attempting to force the gear down. One method is to dive the airplane (in smooth air only) to VNE speed (red line on the airspeed indicator) and (within the limits of safety) execute a rapid pull up. In normal category airplanes, this procedure will create a 3.8 G load on the structure, in effect making the landing gear weigh 3.8 times normal. In some cases, this may force the landing gear into the down and locked position. This procedure requires a fine control touch and good feel for the airplane. The pilot must avoid exceeding the design stress limits of the airplane while attempting to lower the landing gear. The pilot must also avoid an accelerated stall and possible loss of control while attention is directed to solving the landing gear problem.

Another method that has proven useful in some cases is to induce rapid yawing. After stabilizing at or slightly less than maneuvering speed (VA), the pilot should alternately and aggressively apply rudder in one direction and then the other in rapid sequence. The resulting yawing action may cause the landing gear to fall into place.

If all efforts to extend the landing gear have failed, and a gear up landing is inevitable, the pilot should select an airport with crash and rescue facilities. The pilot should not hesitate to request that emergency equipment be standing by.

When selecting a landing surface, the pilot should consider that a smooth, hard-surface runway usually causes less damage than rough, unimproved grass strips. A hard surface does, however, create sparks that can ignite fuel. If the airport is so equipped, the pilot can request that the runway surface be foamed. The pilot should consider burning off excess fuel. This will reduce landing speed and fire potential.

Ch 16.qxd 5/7/04 10:30 AM Page 16-10If the landing gear malfunction is limited to one main landing gear leg, the pilot should consume as much fuel from that side of the airplane as practicable, thereby reducing the weight of the wing on that side. The reduced weight makes it possible to delay the unsupported wing from contacting the surface during the landing roll until the last possible moment. Reduced impact speeds result in less damage.

If only one landing gear leg fails to extend, the pilot has the option of landing on the available gear legs, or landing with all the gear legs retracted. Landing on only one main gear usually causes the airplane to veer strongly in the direction of the faulty gear leg after touchdown. If the landing runway is narrow, and/or ditches and obstacles line the runway edge, maximum directional control after touchdown is a necessity. In this situation, a landing with all three gear retracted may be the safest course of action.

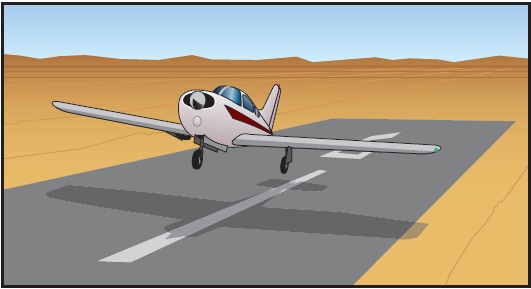

If the pilot elects to land with one main gear retracted (and the other main gear and nose gear down and locked), the landing should be made in a nose-high attitude with the wings level. As airspeed decays, the pilot should apply whatever aileron control is necessary to keep the unsupported wing airborne as long as possible. [Figure 16-7] Once the wing contacts the surface, the pilot can anticipate a strong yaw in that direction. The pilot must be prepared to use full opposite rudder and aggressive braking to maintain some degree of directional control.

Figure 16-7. Landing with one main gear retracted.

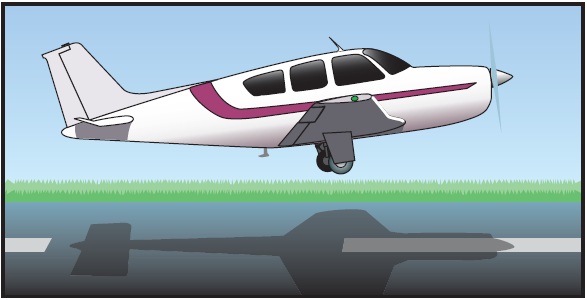

When landing with a retracted nosewheel (and the main gear extended and locked) the pilot should hold the nose off the ground until almost full up-elevator has been applied. [Figure 16-8] The pilot should then release back pressure in such a manner that the nose settles slowly to the surface. Applying and holding full up-elevator will result in the nose abruptly dropping to the surface as airspeed decays, possibly resulting in burrowing and/or additional damage. Brake pressure should not be applied during the landing roll unless absolutely necessary to avoid a collision with obstacles.

16-10

Figure 16-8. Landing with nosewheel retracted.

If the landing must be made with only the nose gear extended, the initial contact should be made on the aft fuselage structure with a nose-high attitude. This procedure will help prevent porpoising and/or wheelbarrowing. The pilot should then allow the nosewheel to gradually touch down, using nosewheel steering as necessary for directional control.

PED Publication