Chapter 14—Transition to Turbopropeller Powered Airplanes

Table of Contents

General

The Gas Turbine Engine

Turboprop Engines

Turboprop Engine Types

Fixed Shaft

Split-Shaft / Free Turbine Engine

Reverse Thrust and Beta Range Operations

Turboprop Airplane Electrical Systems

Operational Considerations

Training Considerations

THE GAS TURBINE ENGINE

Both piston (reciprocating) engines and gas turbine engines are internal combustion engines. They have a similar cycle of operation that consists of induction, compression, combustion, expansion, and exhaust. In a piston engine, each of these events is a separate distinct occurrence in each cylinder. Also, in a piston engine an ignition event must occur during each cycle, in each cylinder. Unlike reciprocating engines, in gas turbine engines these phases of power occur simultaneously and continuously instead of one cycle at a time. Additionally, ignition occurs during the starting cycle and is continuous thereafter.

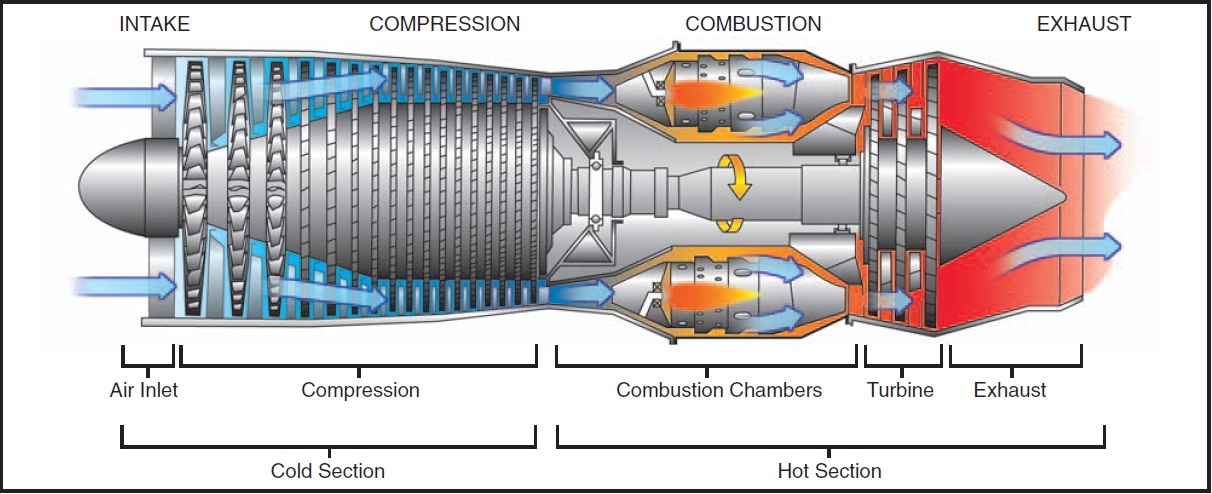

The basic gas turbine engine contains four sections: intake, compression, combustion, and exhaust. [Figure 14-1]

Figure 14-1. Basic components of a gas turbine engine.

To start the engine, the compressor section is rotated by an electrical starter on small engines or an air driven starter on large engines. As compressor r.p.m. accelerates, air is brought in through the inlet duct, compressed to a high pressure, and delivered to the combustion section (combustion chambers). Fuel is then injected by a fuel controller through spray nozzles and ignited by igniter plugs. (Not all of the compressed air is used to support combustion. Some of the compressed air bypasses the burner section and circulates within the engine to provide internal cooling.) The fuel/air mixture in the combustion chamber is then burned in a continuous combustion process and produces a very high temperature, typically around 4,000°F, which heats the entire air mass to 1,600 – 2,400°F. The mixture of hot air and gases expands and is directed to the turbine blades forcing the turbine section to rotate, which in turn drives the compressor by means of a direct shaft. After powering the turbine section, the high velocity excess exhaust exits the tail pipe or exhaust section. Once the turbine section is powered by gases from the burner section, the starter is disengaged, and the igniters are turned off. Combustion continues until the engine is shut down by turning off the fuel supply.

Ch 14.qxd 5/7/04 10:08 AM Page 14-2

High-pressure exhaust gases can be used to provide jet thrust as in a turbojet engine. Or, the gases can be directed through an additional turbine to drive a propeller through reduction gearing, as in a turbopropeller (turboprop) engine.

PED Publication