11—Transition to Complex Airplanes

Table of Contents

High Performance and Complex Airplanes

Wing Flaps

Function of Flaps

Flap Effectiveness

Operational Procedures

Controllable-Pitch Propeller

Constant-Speed Propeller

Takeoff, Climb, and Cruise

Blade Angle Control

Governing Range

Constant-Speed Propeller Operation

Turbocharging

Ground Boosting vs. Altitude Turbocharging

Operating Characteristics

Heat Management

Turbocharger Failure

Overboost Condition

Low Manifold Pressure

Retractable Landing Gear

Landing Gear Systems

Controls and Position Indicators

Landing Gear Safety Devices

Emergency Gear Extension Systems

Operational Procedures PreFlight

Takeoff and Climb

Approach and Landing

Transition Training

OPERATIONAL PROCEDURES

PREFLIGHT

Because of their complexity, retractable landing gears demand a close inspection prior to every flight. The inspection should begin inside the cockpit. The pilot should first make certain that the landing gear selector switch is in the GEAR DOWN position. The pilot should then turn on the battery master switch and ensure that the landing gear position indicators show that the gear is down and locked.

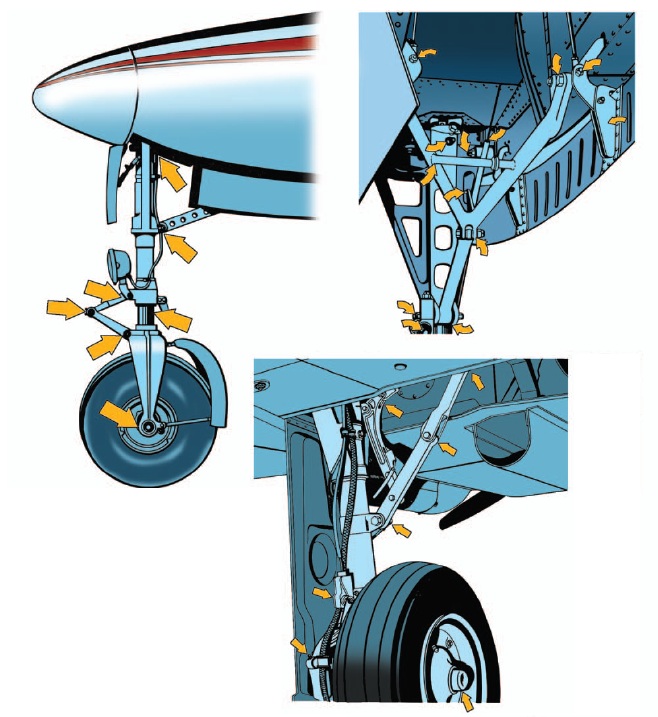

External inspection of the landing gear should consist of checking individual system components. [Figure 11-10] The landing gear, wheel well, and adjacent areas should be clean and free of mud and debris. Dirty switches and valves may cause false safe light indications or interrupt the extension cycle before the landing gear is completely down and locked. The wheel wells should be clear of any obstructions, as foreign objects may damage the gear or interfere with its operation. Bent gear doors may be an indication of possible problems with normal gear operation.

TAKEOFF AND CLIMB

Normally, the landing gear should be retracted after lift-off when the airplane has reached an altitude where, in the event of an engine failure or other emergency requiring an aborted takeoff, the airplane could no longer be landed on the runway. This procedure, however, may not apply to all situations. Landing gear retraction should be preplanned, taking into account the length of the runway, climb gradient, obstacle clearance requirements, the characteristics of the terrain beyond the departure end of the runway, and the climb characteristics of the particular airplane. For example, in some situations it may be preferable, in the event of an engine failure, to make an off airport forced landing with the gear extended in order to take advantage of the energy absorbing qualities of terrain (see Chapter 16). In which case, a delay in retracting the landing gear after takeoff from a short runway may be warranted. In other situations, obstacles in the climb path may warrant a timely gear retraction after takeoff. Also, in some airplanes the initial climb pitch attitude is such that any view of the runway remaining is blocked, making an assessment of the feasibility of touching down on the remaining runway difficult.

Premature landing gear retraction should be avoided. The landing gear should not be retracted until a positive rate of climb is indicated on the flight instruments. If the airplane has not attained a positive rate of climb, there is always the chance it may settle back onto the runway with the gear retracted. This is especially so in cases of premature lift-off. The pilot should also remember that leaning forward to reach the landing gear selector may result in inadvertent forward pressure on the yoke, which will cause the airplane to descend.

As the landing gear retracts, airspeed will increase and the airplane’s pitch attitude may change. The gear may take several seconds to retract. Gear retraction and locking (and gear extension and locking) is accompanied by sound and feel that are unique to the specific make and model airplane. The pilot should become familiar with the sounds and feel of normal gear retraction so that any abnormal gear operation can be readily discernable. Abnormal landing gear retraction is most often a clear sign that the gear extension cycle will also be abnormal.

Figure 11-10. Retractable landing gear inspection checkpoints.

Shock struts should be properly inflated and the pistons clean. Main gear and nose gear uplock and downlock mechanisms should be checked for general condition. Power sources and retracting mechanisms should be checked for general condition, obvious defects, and security of attachment. Hydraulic lines should be checked for signs of chafing, and leakage at attach points. Warning system micro switches (squat switches) should be checked for cleanliness and security of attachment. Actuating cylinders, sprockets, universals, drive gears, linkages and any other accessible components should be checked for condition and obvious defects. The airplane structure to which the landing gear is attached should be checked for distortion, cracks, and general condition. All bolts and rivets should be intact and secure.

11-12

Ch 11.qxd 5/7/04 8:50 AM Page 11-13

APPROACH AND LANDING

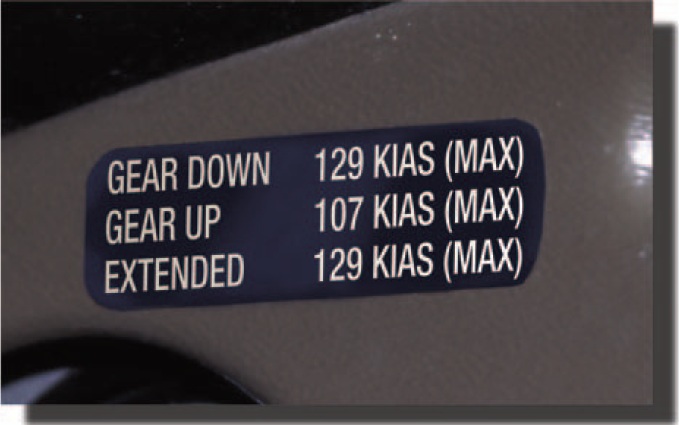

The operating loads placed on the landing gear at higher airspeeds may cause structural damage due to the forces of the airstream. Limiting speeds, therefore, are established for gear operation to protect the gear components from becoming overstressed during flight. These speeds are not found on the airspeed indicator. They are published in the AFM/POH for the particular airplane and are usually listed on placards in the cockpit. [Figure 11-11] The maximum landing extended speed (VLE ) is the maximum speed at which the airplane can be flown with the landing gear extended. The maximum landing gear operating speed (VLO) is the maximum speed at which the landing gear may be operated through its cycle.

Figure 11-11. Placarded gear speeds in the cockpit.

The landing gear is extended by placing the gear selector switch in the GEAR DOWN position. As the landing gear extends, the airspeed will decrease and the pitch attitude may increase. During the several seconds it takes for the gear to extend, the pilot should be attentive to any abnormal sounds or feel. The pilot should confirm that the landing gear has extended and locked by the normal sound and feel of the system operation as well as by the gear position indicators in the cockpit. Unless the landing gear has been previously extended to aid in a descent to traffic pattern altitude, the landing gear should be extended by the time the airplane reaches a point on the downwind leg that is opposite the point of intended landing. The pilot should establish a standard procedure consisting of a specific position on the downwind leg at which to lower the landing gear. Strict adherence to this procedure will aid the pilot in avoiding unintentional gear up landings.

Operation of an airplane equipped with a retractable landing gear requires the deliberate, careful, and continued use of an appropriate checklist. When on the downwind leg, the pilot should make it a habit to complete the landing gear checklist for that airplane. This accomplishes two purposes. It ensures that action has been taken to lower the gear, and it increases the pilot’s awareness so that the gear down indicators can be rechecked prior to landing.

Unless good operating practices dictate otherwise, the landing roll should be completed and the airplane clear of the runway before any levers or switches are operated. This will accomplish the following: The landing gear strut safety switches will be actuated, deactivating the landing gear retract system. After rollout and clearing the runway, the pilot will be able to focus attention on the after landing checklist and to identify the proper controls.

Pilots transitioning to retractable gear airplanes should be aware that the most common pilot operational factors involved in retractable gear airplane accidents are:

- Neglected to extend landing gear.

- Inadvertently retracted landing gear.

- Activated gear, but failed to check gear position.

- Misused emergency gear system.

- Retracted gear prematurely on takeoff.

- Extended gear too late.

In order to minimize the chances of a landing gear related mishap, the pilot should:

- Use an appropriate checklist. (A condensed checklist mounted in view of the pilot as a reminder for its use and easy reference can be especially helpful.)

- Be familiar with, and periodically review, the landing gear emergency extension procedures for the particular airplane.

- Be familiar with the landing gear warning horn and warning light systems for the particular airplane. Use the horn system to cross-check the warning light system when an unsafe condition is noted.

- Review the procedure for replacing light bulbs in the landing gear warning light displays for the particular airplane, so that you can properly replace a bulb to determine if the bulb(s) in the display is good. Check to see if spare bulbs are available in the airplane spare bulb supply as part of the preflight inspection.

- Be familiar with and aware of the sounds and feel of a properly operating landing gear system.

Ch 11.qxd 5/7/04 8:50 AM Page 11-14

PED Publication